Subleem™

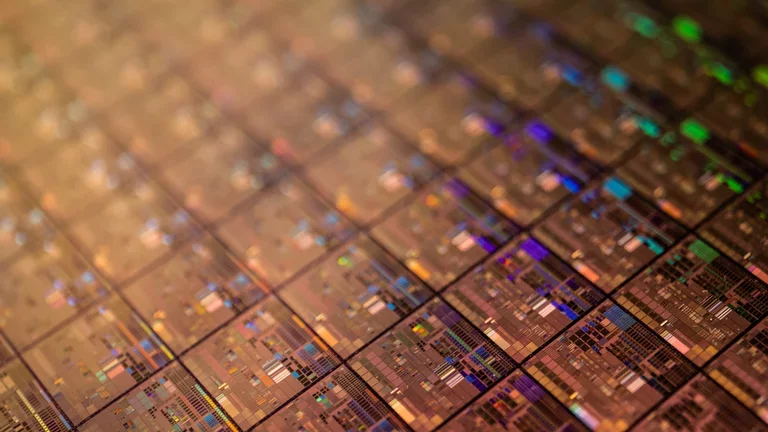

Enabling Molybdenum metallization using high purity solid precursors and first of a kind gas-phase distribution systems.

Leading-edge Technology for uninterrupted, high flowrate, sublimized metal chloride precursors

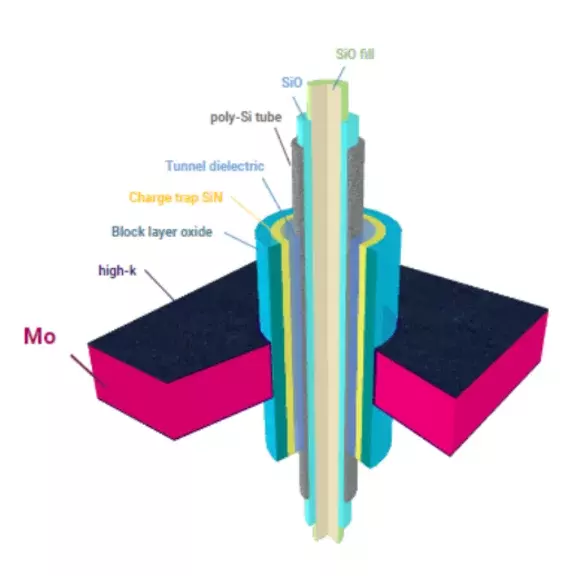

Thanks to its superior vapor delivery capabilities, SubleemTM enables the adoption of solid precursors such as Molybdenum Chlorides as key materials for new generations of 3D-NAND architectures enabling improved reading and writing speeds. While solid metal chlorides have been used for over two decades as thin film precursors in the semiconductor industry, their range of application has been limited to ultra-thin small volume layers due to their gas phase delivery challenges until now.

Years of expertise in gas-phase delivery systems enabling applications in latest 3D-NAND architectures

Air Liquide engineers developed a series of new proprietary large scale sublimation systems (OVC(1) and SSS(2)) capable of delivering a high flux of gas phase sublimized precursors simultaneously to multiple tools, maximizing deposition equipment uptime. The OVC and SSS units operate in carefully engineered conditions to deliver corrosive, sublimized precursors to the deposition tools from major OEMs(3) which are used by advanced logic and memory manufacturers.

Our systems provide best-in-class performance enabling precise control over the precursor flux while providing low Total Cost of Ownership. They are compatible with containers ranging from small to bulk size. Our systems (OVC and SSS units) are uniquely designed to meet the needs of the different OEM platforms.

Our family of high purity molybdenum solid chlorides includes MoCl5 and MoO2Cl2 for applications in logic, DRAM, and NAND devices.

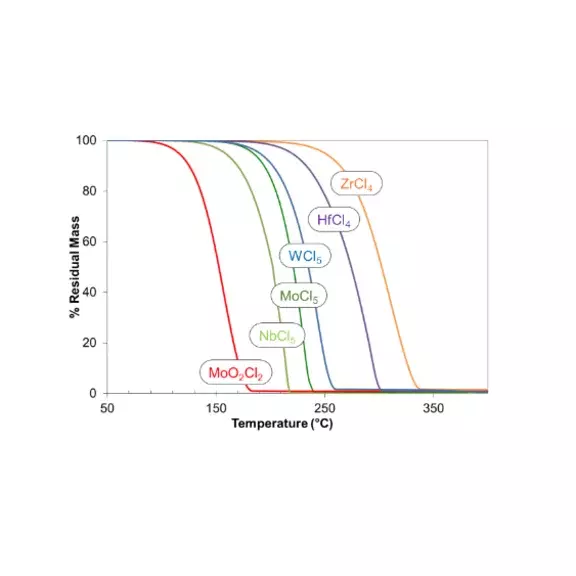

Beyond MoO2Cl2 and MoCl5, our SubleemTM precursors portfolio covers a family of high purity metal chlorides: AlCl3, HfCl4, WCl5, WCl6, WOCl4, TaCl5, NbCl5 and ZrCl4. SubleemTM precursors are used to manufacture among the most critical layers of semiconductor architectures, such as high-k gate oxide, metal gate, control electrodes and metal interconnects.

Ensuring quality, safety and reliability

Air Liquide developed proprietary manufacturing processes to remove metallic impurities from the solid chlorides, down to part-ber-billion (ppb) levels, ensuring a repeatable, contaminant free, deposition. To deliver best-in-class analytical and quality performance for SubleemTM precursors, Air Liquide BalazsTM lab is equipped with state-of-the-art metrology techniques(4).

Our SubleemTM precursors are produced in our facilities in the USA, Japan, Taiwan and Korea in highly controlled packages. Smaller containers are used on-board tools or for higher throughput, bulk supply systems in fab utility rooms. Air Liquide packaging experts are trained to design, assemble and maintain fleets of sublimator packages to ensure a continuous and defect free operation.

SSS(2): Solid Sublimation System

OEM(3): Original Equipment Manufacturers

Metrology techniques(4): including X-Ray Diffraction (XRD), high-resolution Inductively Coupled Plasma Mass Spectrometry (ICPMS), Thermal Gravimetric Analysis (TGA), Fourrier-Transform Infra-Red Spectrometry (FT-IR).