Photovoltaics

Higher efficiency photovoltaic systems for lower cost

As the world turns to renewables, solar photovoltaic system installation has been steadily increasing. The global solar photovoltaic end-market has maintained double-digit growth in certain geographies, with various financial supports from governments.

After a long period of evolution, solar photovoltaic manufacturing has split into two main fields: crystalline silicon (c-Si) with 90% of the global production, and thin film (TF) solar.

Innovation for a brighter future

To provide more affordable solar energy, the entire photovoltaic supply chain is in need of new materials and technologies that drive panel performance up and costs down.

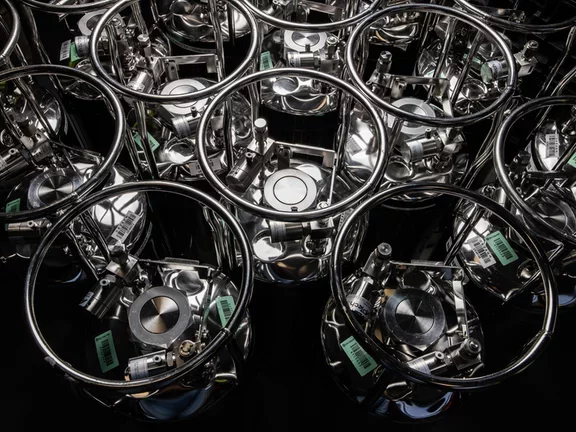

Our recent investment in a crystalline silicon solar cells demonstration and pilot production line, extensive R&D and academic collaborations, and innovative product offerings, are just some examples of our work in the field.

As a result, we are able to respond promptly with the right solution for technology problems and, most important of all, create value for our customers.

Turnkey solutions for the photovoltaic industry

Since investing in monosilane production in Japan for the semiconductor and photovoltaic industries in 1987, we have been committed to accompanying the industry towards sustainability, profitability and growth.

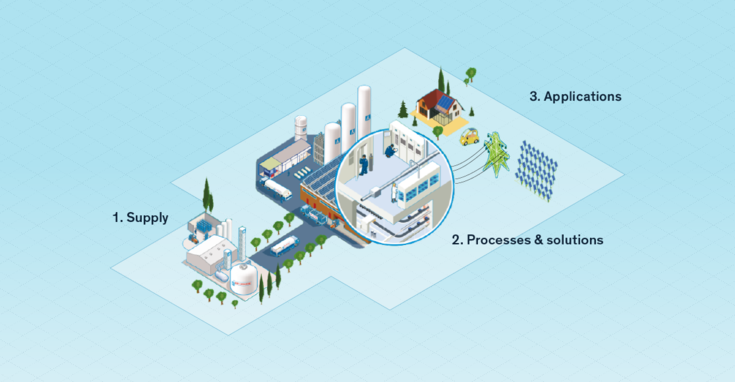

A leading supplier across the entire photovoltaic supply chain

- Air Liquide supplies air gases (nitrogen, argon, etc.), specialty gases (silane, ammoniac, etc.), and advanced precursors.

- These gases and precursors are used to:

- etch silicon wafers

- render them semiconducting, i.e., able to produce electricity via the diffusion of phosphorus

- cover them with an anti-reflection coating to maximize light transmission

- improve yields with innovative coatings

- The challenge is to provide efficient precursors that allow manufacturers to optimize their production costs and, in so doing, make photovoltaic electricity competitive.

- The use of solar energy to meet the electricity needs – of individuals, power plants, remote sites, etc. – is on the rise.