Electronics Advanced Materials

Essential materials at the heart of microprocessors

Enabling next-generation manufacturing technologies

Enhanced connectivity, computing power, longer battery life, and all-round better mobility are the hallmarks of today’s global consumer electronics market.

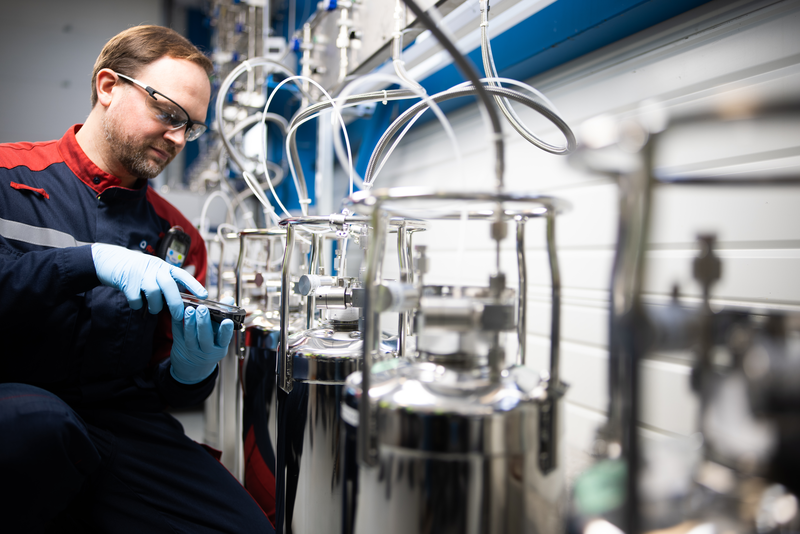

To achieve this performance, products rely on new generations of semiconductor chips, which are enabled by novel materials. These high-tech materials are deposited during chip fabrication via Chemical Vapor Deposition (CVD) and Atomic Layer Deposition (ALD) processes, using a wide range of electronics advanced materials that we produce. Complex 3D structures are created by combining deposition with Reactive Ion Etching and Atomic Layer Etching.

Collaboration with customers and OEMs for new material development

Air Liquide is the industry leader in advanced thin-film materials, offering the ALOHA™ and Voltaix™ product lines as part of our material portfolio. The acquisition of Voltaix™, the recognized world leader in silicon, germanium, and boron chemistries, in 2013, has bolstered our positioning. We have extended our range of advanced precursors, strengthened our relations with key customers and partners, and created new synergies in the research and industrialization of electronics advanced materials.

As increasingly complex 3D structures have been deployed to make the latest, high-density memory and logic chips, Air Liquide has extended its offer to include enScribe™ etchants.

We partner with our semiconductor customers and Original Equipment Manufacturers (OEMs) to select the most appropriate electronics advanced materials for their exact process requirements and design new materials when necessary.

Our materials offering covers a broad range of advanced deposition processes, ranging from low-k to high-k and metals to barrier films. We also offer advanced etching gases.

Air Liquide’s comprehensive offer includes dedicated OEM-qualified delivery systems, ultra-high purity canisters, consistent manufacturing practices, and extremely tight specifications, backed by world-class Air Liquide affiliates in the nano-scale analysis (Balazs™).

Global capabilities

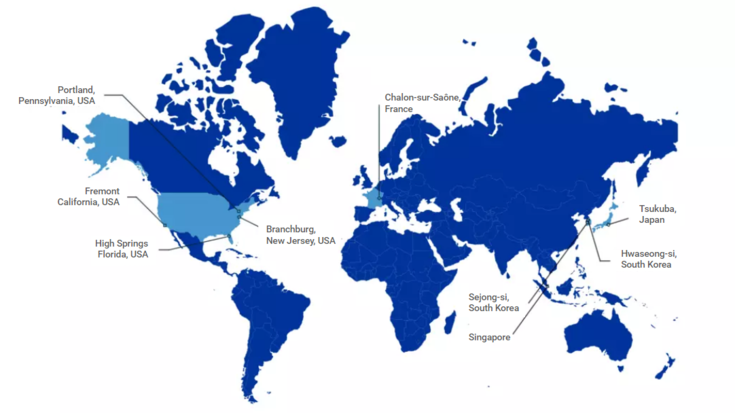

Air Liquide’s global capabilities include 10 Advanced Materials Centers (AMCs) where we produce, package, and certify advanced electronics materials ensuring the safety of supply and matching quality expectations of our most demanding customers. These centers are strategically located in electronics hubs including South Korea, Japan, Singapore, the USA, and Europe.