Semiconductors

Enhancing production yields and ramping-up the next generation

In the world of the semiconductor industry, size always matters. Integral to everything from processors found inside smartphones or computers to memory chips and image sensors, the use of semiconductor chips or integrated-circuits is now spreading outside the digital world. With every new application and end-user expectations for more performances come ever-greater challenges to produce smaller and more cost-efficient semiconductor chips. Manufacturers can rely on Air Liquide to meet these needs.

Growing market for semiconductors

Semiconductor chips (also called integrated-circuits) are basically computing processors, memories, sensors, micro-controllers, power devices and other devices.

Although they are used primarily in computers, we serve more and more the semiconductors manufacturers worldwide by improving the connectivity and performance of smartphones and tablets. Today, the use of chips is spreading to new areas. Just one example is the automotive industry, where integrated-circuits, are replacing mechanical or fluidic systems for acceleration and braking control and enabling smart anti-collision systems. Connected smart objects or so called “Internet of Things”, are also incorporating semiconductors.

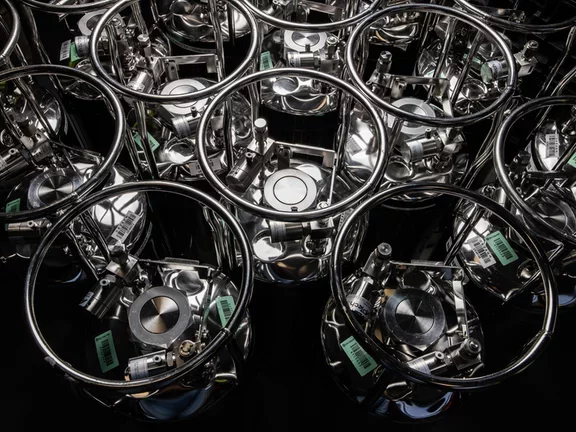

Air Liquide accompanies semiconductor manufacturers, delivering the ultra-high purity carrier gases needed to keep their manufacturing processes clean and stable over time. We also supply the specialty and advanced electronics materials (also called precursor molecules) to produce the semiconductor chips, and provide the equipment and services for the safe and optimum handling and distribution of our products.

“Air Liquide’s ALOHA™ offer is a leading participant in the innovation race to enable the increase in computing power and connectivity for consumers through cutting-edge advances in high performance electronics materials.

”

Ashutosh Misra

Group Vice President, Sustainable Development

Innovation in electronics advanced materials

Since their discovery in the late 1950s, the development of semiconductor chips, also called integrated-circuits, has more or less adhered to Moore’s Law. This rule, established by Intel founder Gordon Moore, stated that computing power should double every two years at constant costs.

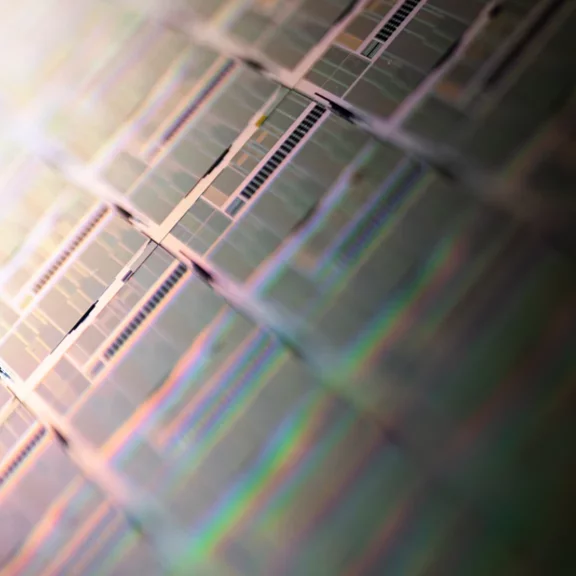

Meeting these challenges requires miniaturization of the billions of transistors or “digital semiconductor switches” behind each integrated circuit. Miniaturization allows more chips on the same substrate surface. A second benefit of miniaturization enables the chips to run faster thanks to shorter internal structure and electrical connections. As a result, billions of transistors can be found on several dozen layers and on a 1 cm² surface.

Materials used to build transistors present a predetermined set of specific electrical properties. At each step of miniaturization, it is essential to improve the conduction of the chip’s constituent, sometimes requiring new materials and molecules precursors. Air Liquide offers the best adapted products to optimize the manufacturing process and electrical chip’s performance. Thus, we are involved in developing new generations of more efficient chips.

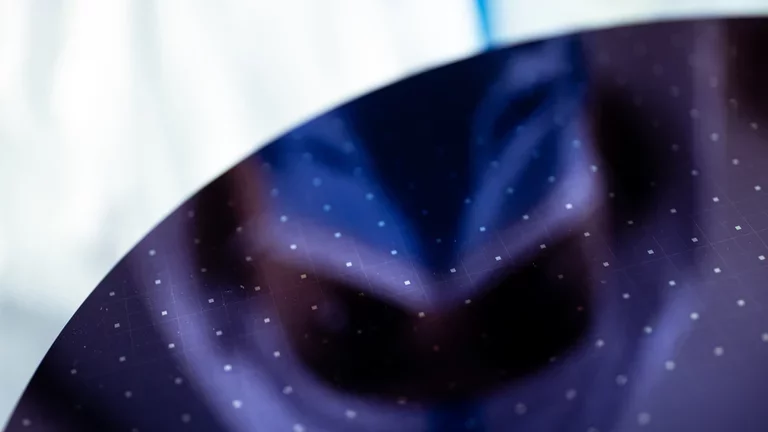

A large portfolio of electronics advanced materials

For each new generation of semiconductors, Air Liquide invents and produces electronics advanced materials with specific chemical, thermal, physical and high-purity properties for semiconductor customers. These innovative molecules are supplied in liquid form in ultra-high purity canisters and dispensed to the manufacturing equipment. The molecules are then vaporized and deposited precisely at the nano-scale level, forming successive and uniform layers of chip constituent materials.

We are also partnering with leading customers and technology centers of excellence to conceive new molecules that respond to emerging semiconductor industry technology challenges.